ENVIRONMENTAL SUSTAINABILITY

At P&G, environmental sustainability is embedded in how we do business. We make people’s everyday lives a little better. However, while our commitment to “better” has never changed, the standard we need to deliver on has. More and more for our consumers, better for them, without better for the planet, is no longer better. We share that conviction. Innovation cannot be irresistibly superior without also being sustainable. Together in partnership we can build a better future for all. After all, it’s our home. And our window is now.

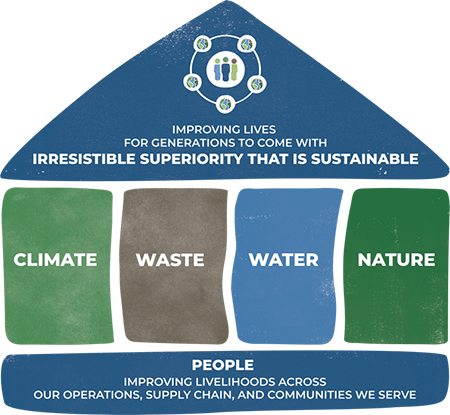

P&G’s Ambition 2030 supports our brands’ ability to provide irresistible superiority that is sustainable to improve lives now and for generations to come. At its foundation is improving the livelihoods of people across our operations, supply chain, and the communities we serve. It is built upon the strength of four science-based pillars—Climate, Waste, Water and Nature—where we can make the biggest difference for the planet and our business.

Climate

Climate

NET ZERO AMBITION BY 2040

In September 2021, P&G set a new ambition to achieve net zero greenhouse gas (GHG) emissions across its operations and supply chain, from raw material to retailer. P&G also shared a Climate Transition Action Plan which outlines a comprehensive approach to accelerating climate action and the key challenges ahead. In addition to the details of P&G’s net zero ambition to 2040, the Climate Transition Action Plan covers the entire lifecycle emissions of our products and packaging, across supply chain, operations, consumer use of our products, and product end of life.

To learn more about the progress we are making against our climate goals, click here.

Waste

Waste

Plastic waste in our environment is a serious problem, especially when it ends up in our rivers and oceans. It’s a complex global challenge that requires a comprehensive, collaborative approach across the entire plastics lifecycle. Addressing this challenge and driving greater circularity for plastics will require collaboration across multiple stakeholders, including industry, governments, civil society and academics. While plastic can provide packaging material reductions, product protection, and lower greenhouse gas emissions from transportation, we must use and reuse it responsibly.

At P&G, we are working to design all our consumer packaging to be recyclable or reusable by 2030. We are inventing and scaling new recycling solutions, using alternative materials, and partnering externally to help catalyse waste management infrastructure to improve access to collection — keeping plastic in use and out of nature.

To learn more about the progress we are making against our packaging goals, click here.

Water

Water

At P&G, we want to help build a water positive future that can sustain people and nature, now and for generations to come. In June 2022, we announced a comprehensive strategy, that includes restoring water in water-stressed areas for people and nature, responding to water challenges through innovation and partnerships, and reducing water in our operations to help conserve local water supplies. We’ve also set 2030 goals to restore more water than is consumed1 at P&G manufacturing sites in 18 water-stressed areas around the world; and to restore more water than is consumed2 when using P&G products in high water-stressed metropolitan areas of Los Angeles and Mexico City. We will achieve these goals through partnerships and restoration projects that improve, manage, and protect water resources.

To learn more about the progress we are making against our water goals, click here.

1 Water that evaporates during the manufacturing of our products or is incorporated into the finished product manufactured at these sites.

2 Water from household leaks and evaporation during the use of our products.

Nature

Nature

At P&G, we are committed to the long-term health of natural ecosystems that are essential to people, biodiversity and our business. Our efforts start with ensuring responsible sourcing of key commodities like wood pulp, palm oil and paper packaging.

We also go beyond our direct supply chain to protect, improve and restore ecosystems in more places, where it matters most. We are partnering and investing in nature-based solutions to positively impact more than 1.5 million acres of land, balance any remaining carbon emissions from our manufacturing operations this decade, and enable positive outcomes for people and biodiversity.

To learn more about the progress we are making against our goals, click here.

Saving Energy at Home

Since 2015, P&G brands Tide and Ariel have helped consumers increase their use of low-energy laundry cycles to avoid roughly 15 million metric tons of carbon dioxide. We have leveraged innovation and sustained consumer education to help reduce the largest portion of our carbon footprint — the energy needed to heat water during product use.

Our work doesn't stop here

For more information, visit our ESG Investor Portal where you can find out more about P&G goals, efforts and progress on water, waste, climate, forestry, equality and inclusion and governance, among others. For specific information about our different programs and activities on how we are helping make our home better across forestry, plastic packaging, water and climate, visit Mapping Our Impact section on our public website.

History of P&G Sustainability.

To see the full history of our environmental sustainability efforts, take a look at our timeline.