Environmental Sustainability

At P&G, environmental sustainability is embedded in how we do business. We have a responsibility to make the world better. P&G is committed to positively impacting our homes, our communities, and our planet — especially in the areas of Climate, Forestry, Water and Packaging. We are focused on developing innovations and products that deliver irresistible superiority in a sustainable way. We continue to reduce our footprint and strive for more circular approaches in our supply chain. We’re building partnerships with external organizations to combat some of the most challenging and complex issues we face today. And our employees are committed to ensure that sustainability is built in — not bolted on — to their everyday work. To learn more about what we are doing in the areas of climate, water, forestry and packaging, click here.

Net Zero Ambition by 2040

Net Zero Ambition by 2040

In September 2021, P&G set a new ambition to achieve net zero greenhouse gas (GHG) emissions across its operations and supply chain, from raw material to retailer. P&G also shared a Climate Transition Action Plan which outlines a comprehensive approach to accelerating climate action and the key challenges ahead. In addition to the details of P&G’s net zero ambition to 2040, the Climate Transition Action Plan covers the entire lifecycle emissions of our products and packaging, across supply chain, operations, consumer use of our products, and product end of life.

To learn more about the progress we are making against our climate goals, click here.

Ambition 2030

Reducing our carbon emissions, prioritizing water conservation and shifting to renewable electricity are just the beginning. In 2018, we took a hard look and refocused our energy toward 2030, with a new set of goals and an embrace of new practices intended not just to reduce our footprint and conserve precious resources, but to help restore the world, ultimately leaving it better than we found it.

For progress on Ambition 2030, click here.

Collecting, Processing and Recycling Plastic Packaging Waste

We continue to be compliant with the government’s Extended Producer Responsibility (EPR) guidelines on plastic packaging waste collection, recycling, and processing. In line with this, this year we have collected, processed, and recycled more than 23000 MT of plastic packaging waste, over and above the quantum of plastic packaging used in our products and that mandated for the year under the EPR guidelines, hence maintaining plastic packaging waste neutrality.

Our plants are leveraging solar energy

We are committed to setting up two more in-house solar plants at our manufacturing sites in Goa and Mandideep, to leverage the power of renewable energy and contribute towards safeguarding the environment. This is in addition to the existing in-house solar plant we had set up in 2019 at our manufacturing site in Hyderabad. This puts us among the few companies in India that have three in-house solar plants at their manufacturing sites.

We are progressing in our focus areas

We have made significant progress across our focus areas of climate, water and waste. We purchase 100% renewable energy for all our manufacturing sites. Five of our manufacturing sites have already achieved the 2030 target of 35% water efficiency. Further, all our manufacturing sites are zero waste to landfill, which means that no manufacturing waste is discharged into the environment. We have also installed electronic vehicle (EV) charging stations at our India headquarters in Mumbai to facilitate our people as they make a transition towards greener commuting

Water Strategy

We recently announced a global water strategy which aims to restore water in 18 water-stressed areas around the world for people and nature, responding to water challenges through innovation and partnerships, and reducing water in our operations. Out of these 18 water-stressed areas, 5 are in India. Globally, we are doing our part to conserve and restore water for people and nature. In 2020, we kicked off a partnership with the Bonneville Environmental Foundation (BEF) Business for Water Stewardship (BWS) program through which we are funding six projects in California’s Sacramento River and American River basins that aim to have a longterm positive impact on freshwater ecosystems and water supply for communities and businesses. These projects, combined, expect to restore more than three billion liters of water to people and nature. We have also increased water efficiency in our operations by 25%1 per unit of production and sourced 3.1 billion liters of water from circular sources.

Our brands are leading the change

The P&G brands have also stepped forward towards environmental sustainability. We are among the few companies in India to use recycled material in the packaging of our Baby care and Feminine care packaging. This will reduce usage of 500MT virgin plastic annually. Our brand Venus is made with 30% recycled plastic and uses fully recyclable packaging. Moreover, the liquid-detergent bottle by our brand Ariel is recyclable. Further, our brands Ariel and Tide continue to be phosphate free.

Joining forces on environmental sustainability

In 2019, we joined forces with more than 40 companies globally that make plastic, use plastic in their products and packaging, and those who recycle and manage plastic waste to form The Alliance to End Plastic Waste. The Alliance is supporting an array of projects and partnerships that focus on solutions in four core areas: infrastructure, innovation, education and cleanup, with particular emphasis where the need is most urgent in Southeast Asia including India.

P&G has also joined its fellow investors and Circulate Capital in an effort to combat plastic that pollutes the world’s oceans. Together, our vision is to advance a carbon-beneficial circular economy and prevent the flow of plastic waste into the oceans. In India, the focus is to incentivize the unorganized sector through investments in businesses, value-adding to collection and sorting of waste, and expansion of plastic waste processing and recycling capacity.

Our work doesn't stop here

For more information, visit our ESG Investor Portal where you can find out more about P&G goals, efforts and progress on water, waste, climate, forestry, equality and inclusion and governance, among others. For specific information about our different programs and activities on how we are helping make our home better across forestry, plastic packaging, water and climate, visit Mapping Our Impact section on our public website.

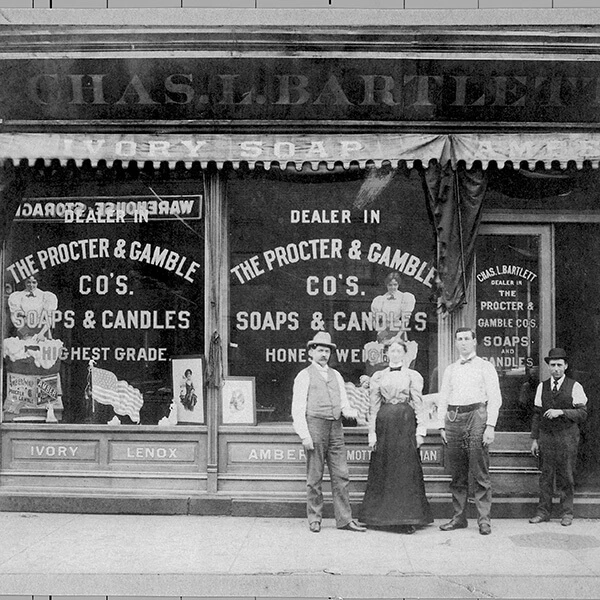

History of P&G sustainability

To see the full history of our environmental sustainability efforts, have a look at our timeline.